16 September 2025

In the modern sports infrastructure landscape, the demand for high-performance, durable, and low-maintenance playing surfaces has significantly accelerated the adoption of artificial football ground solutions. These advanced systems, encompassing everything from the turf itself to the underlying base, offer unparalleled advantages over natural grass. As a professional manufacturer, XYGrass is at the forefront of this evolution, adhering to high standards from raw material selection to production processes. Our commitment is to provide premium solutions for various soccer fields, including state-of-the-art artificial football pitches that meet the stringent requirements of professional play and community use. The seamless integration of cutting-edge technology ensures that every artificial football ground delivers consistent performance, safety, and longevity.

The industry trend indicates a clear shift towards sustainable and resilient sporting facilities. Modern artificial football pitches are designed to withstand intensive usage, diverse weather conditions, and require minimal upkeep, making them an economically viable and environmentally conscious choice. Our flagship product, Football Grass (FG50), embodies these principles, offering superior playability and an extended lifespan. This dedication to quality ensures that every artificial grass football ground we produce is not just a playing surface, but an investment in future sporting excellence.

Understanding the technical specifications is crucial for selecting the optimal artificial football ground. Key parameters such as pile height, Dtex, gauge, stitch rate, and backing material directly influence the performance, durability, and feel of the artificial grass football pitch. These metrics are critical for ensuring player safety, ball roll consistency (an important consideration for an artificial grass football ball), and the overall resilience of the surface. Below is a general overview of common parameters found in high-quality artificial football grounds:

Parameter | Typical Range/Value | Impact on Performance |

Pile Height | 40mm – 60mm | Affects ball roll, shock absorption, and infill retention. Shorter piles for hockey, longer for artificial football pitches. |

Dtex (Decitex) | 8,000 – 15,000 | Indicates fiber strength and density. Higher Dtex means more durable yarn for the artificial football ground. |

Gauge | 3/8 inch, 5/8 inch | Distance between stitch lines. Influences turf density and visual appearance of the artificial grass football ground. |

Stitch Rate | 160 – 200 stitches/meter | Number of stitches per 10cm or meter. Higher stitch rate means denser turf, better wear resistance for artificial football pitches. |

Backing Material | PP + Non-woven, SBR Latex/PU Coating | Provides dimensional stability, strength, and secures the turf fibers. PU backing offers superior stability and longer life for an artificial football ground. |

Infill Type | SBR, EPDM, TPE, Crumb Rubber, Sand | Crucial for shock absorption, ball bounce, stability, and temperature regulation in an artificial grass football pitch. |

The precise combination of these parameters is engineered to replicate the playing characteristics of natural grass while offering enhanced resilience. This meticulous attention to detail ensures that an artificial football ground from XYGrass not only meets but often exceeds industry benchmarks for safety and playability.

The production of a high-quality artificial football ground like our FG50 involves a sophisticated multi-stage manufacturing process, emphasizing precision and quality control at every step. This ensures the superior performance and longevity of our artificial football pitches.

1. Raw Material Selection: We meticulously select premium-grade polyethylene (PE) or polypropylene (PP) polymers for the yarn. These materials are chosen for their UV stability, resilience, and non-abrasive properties, which are crucial for the longevity and safety of an artificial grass football ground. Pigments are added at this stage to achieve the desired grass color, ensuring a natural aesthetic for the artificial football ground.

2. Yarn Extrusion: The selected polymers are extruded into monofilament or fibrillated yarns. This process dictates the shape, thickness, and strength of each individual blade of grass, influencing the feel and durability of the artificial football pitches. Our advanced extrusion lines ensure consistent yarn quality, which is vital for a uniform playing surface.

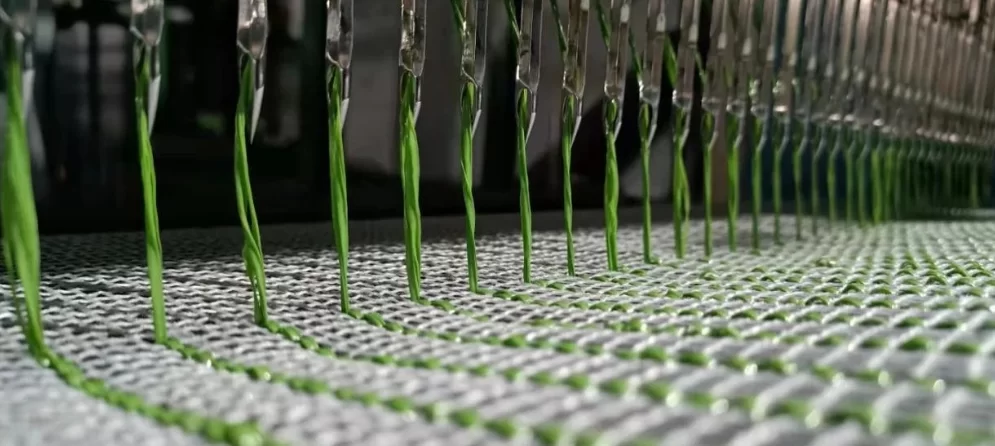

3. Tufting: In this critical stage, thousands of yarn fibers are precisely stitched onto a primary backing material, typically made of woven polypropylene. High-speed tufting machines create uniform rows of artificial grass blades, determining the pile height and gauge. This process is similar to carpet manufacturing but with specialized machinery adapted for turf production, ensuring a dense and robust artificial grass football pitch.

4. Coating and Curing: After tufting, the reverse side of the primary backing is coated with a secondary layer, typically SBR latex or polyurethane (PU). This coating permanently locks the fibers in place, enhances dimensional stability, and provides crucial strength to the artificial football ground. The coated turf then undergoes a curing process in ovens to set the backing firmly. PU backing, for instance, offers superior adhesion and resistance to moisture, extending the lifespan of an artificial football ground significantly.

5. Perforation and Slitting: Drainage holes are strategically perforated through the backing to ensure efficient water runoff, preventing waterlogging on the artificial football pitches. The large rolls of turf are then slit into specified widths, typically 4-meter wide rolls, ready for packaging and transport.

6. Quality Control & Inspection: Each batch undergoes rigorous testing to meet international standards such as ISO 9001 for quality management and ISO 14001 for environmental management. Key performance indicators, including pile height, Dtex, tear strength, UV stability, and permeability, are meticulously checked. This ensures that every artificial football ground leaving our facility adheres to the highest specifications.

This intricate process guarantees that our FG50 Football Grass offers exceptional durability, a consistent playing surface for any artificial grass football ball, and a prolonged service life, making it ideal for high-traffic artificial football stadium applications.

Figure 1: Illustration of a modern artificial football ground manufacturing facility.

Our Football Grass (FG50) product is engineered to deliver a superior playing experience, combining robust construction with advanced fiber technology. This product is specifically designed to meet the rigorous demands of professional artificial football grounds and training facilities, ensuring optimal player interaction and ball dynamics. Its specifications are meticulously balanced for an exceptional artificial grass football pitch.

Indicator | FG50 Specification | Benefit for Artificial Football Ground |

Pile Height | 50mm (+/- 1mm) | Optimized for natural ball roll and player comfort on an artificial football ground. |

Dtex | 12,000 (PE Monofilament) | High durability and resilience, ensuring long-term wear resistance for an artificial football pitch. |

Gauge | 3/4 inch | Provides a dense, uniform surface with excellent infill stability. |

Stitch Rate | 200 stitches/meter | Exceptional turf density, contributing to consistent playing characteristics and robust wear for an artificial grass football ground. |

Total Weight | Approx. 2.6 kg/m² | Indicates robust construction and material quantity, ensuring stability. |

Primary Backing | PP woven cloth + Non-woven fleece | Enhanced dimensional stability and strength for the base of the artificial football pitch. |

Secondary Backing | SBR Latex (UV resistant) | Superior fiber lock and environmental resistance for an artificial football ground. |

UV Stability | DIN 53387 > 6,000 hrs | Guarantees color retention and structural integrity under prolonged sun exposure for an artificial football ground. |

The FG50 is designed to provide excellent shock absorption and minimal skin abrasion, crucial for player safety on an artificial grass football pitch. Its robust construction ensures an extended lifespan, reducing the need for frequent replacement and offering a superior return on investment for an artificial football ground.

The versatility and performance of modern artificial football grounds make them suitable for a diverse range of applications, from amateur leagues to professional artificial football stadium venues. Their technical advantages ensure consistent playability and reduced operational costs.

· Professional Training Facilities: Many elite clubs utilize artificial football pitches for year-round training, ensuring optimal conditions regardless of weather. The consistent surface allows for focused skill development and tactical drills.

· Community and Recreational Fields: Public parks, schools, and local sports centers benefit immensely from artificial grass football ground installations due to their durability and low maintenance, accommodating high usage without degradation.

· Multi-Sport Venues: Artificial football pitches are often integrated into multi-sport complexes, providing flexible usage for football, rugby, and other field sports, maximizing facility utilization.

· Indoor Arenas: For climate-controlled indoor sports facilities, artificial grass football pitches offer a perfect solution, allowing for continuous play irrespective of external environmental conditions.

o All-Weather Playability: Artificial football pitches remain playable in rain, snow, or extreme heat, ensuring schedules are unaffected, a significant advantage over natural grass.

o Reduced Maintenance Costs: Eliminates the need for mowing, watering, fertilizing, and re-seeding. Maintenance primarily involves brushing and infill management, leading to substantial operational savings for an artificial football ground.

o Durability and Longevity: Engineered for intensive use, an artificial grass football ground can withstand significantly more playing hours than natural grass, often with a lifespan exceeding 10-15 years.

o Consistent Playing Surface: Provides a uniform playing field, promoting predictable ball bounce and roll, crucial for fair play and player development, especially for the interaction with an artificial grass football ball.

o Environmental Benefits: Reduces water consumption, eliminates pesticide use, and lessens the carbon footprint associated with maintenance equipment for an artificial football ground.

Feedback from clients consistently highlights the superior playability and cost-effectiveness of XYGrass artificial football pitches. For example, a major municipal sports complex reported a 40% reduction in annual pitch maintenance costs after converting their natural fields to our artificial football ground solutions, alongside a 30% increase in usable playing hours.

Choosing the right manufacturer for your artificial football ground is a strategic decision. XYGrass stands apart through our unwavering commitment to quality, innovation, and comprehensive customer support. While the market offers various providers of artificial football pitches, our approach is rooted in delivering tailor-made solutions that align with specific project requirements, from amateur facilities to professional artificial football stadium constructions.

Our expertise extends beyond merely supplying turf; we offer end-to-end solutions, including site assessment, design consultation, material selection, installation guidance, and post-installation support. This holistic approach ensures that every artificial football ground project is executed flawlessly, meeting both technical specifications and client expectations. We leverage over a decade of experience in the artificial grass industry, with hundreds of successful installations of artificial football pitches worldwide.

§ Tailored Specifications: We can customize pile height, Dtex, color, and backing options to suit specific climate conditions, usage intensity, and budgetary constraints for your artificial football ground.

§ Infill Solutions: Offering a range of infill options, including SBR crumb rubber, EPDM, TPE, and natural alternatives, to optimize shock absorption, ball rebound, and playability of the artificial grass football pitch.

§ Integrated Systems: Beyond the turf, we advise on base construction, drainage systems, shock pads, and line markings to create a complete, high-performance artificial football ground system.

Figure 2: A team installing an artificial football ground.

At XYGrass, authoritativeness and trustworthiness are built into every artificial football ground we produce. We understand that investing in an artificial football pitch is a long-term commitment, and robust quality assurance is paramount. Our products, including FG50, are subjected to stringent internal and third-party testing to comply with international standards.

· ISO 9001:2015: Certified for Quality Management Systems, ensuring consistent product quality from raw material to finished artificial football ground.

· FIFA Quality Programme (QMP) Concept: Our artificial football pitches are designed to meet or exceed the performance requirements set by FIFA for ball-surface interaction, shock absorption, and player-surface interaction, vital for an artificial grass football ball.

· DIN Standards (e.g., DIN 18035-7): Compliance with German industrial standards for artificial sports surfaces, covering aspects like drainage, infill properties, and durability.

· CE Certification: Ensuring our artificial football ground products conform to European health, safety, and environmental protection standards.

· UV Resistance Testing (e.g., DIN 53387): Independent lab tests confirm the superior UV stability of our yarns, guaranteeing colorfastness and material integrity for prolonged outdoor exposure, crucial for any artificial grass football stadium.

XYGrass offers a comprehensive warranty on our artificial football ground products, typically ranging from 8 to 12 years, depending on the product and application. This warranty covers manufacturing defects and significant UV degradation, providing our clients with peace of mind and demonstrating our confidence in the longevity of our artificial football pitches. Our standard delivery lead time is 2-4 weeks for most projects, with expedited options available for urgent requirements. Our dedicated customer support team is available from project inception through the entire lifespan of your artificial football ground.

· Q1: What is Dtex and why is it important for an artificial football ground?

Dtex (Decitex) is a unit of measurement for the linear mass density of fibers, specifically the weight in grams of 10,000 meters of yarn. For an artificial football ground, a higher Dtex typically indicates a thicker, stronger, and more durable yarn fiber, directly contributing to the turf's resistance to wear and its overall lifespan. Our FG50 uses 12,000 Dtex fibers, optimized for high-traffic artificial football pitches.

· Q2: What are the primary infill options for artificial football pitches and their roles?

The primary infill options for an artificial football ground include SBR (Styrene-Butadiene Rubber) crumb rubber, EPDM (Ethylene Propylene Diene Monomer), and TPE (Thermoplastic Elastomer). Infill materials are crucial for cushioning, shock absorption, providing ball rebound, stabilizing the artificial grass fibers, and offering traction for players. They help simulate the feel and performance of natural turf for an artificial grass football ball.

· Q3: How does the backing system impact the durability of an artificial football ground?

The backing system, consisting of primary (e.g., PP woven) and secondary (e.g., SBR latex or PU) layers, provides the foundational strength and dimensional stability for an artificial football ground. A robust backing ensures that the turf fibers are securely locked in place, preventing premature shedding, and offers resistance to expansion, contraction, and moisture, thereby extending the overall lifespan of the artificial football pitch.

· Q4: What are the key considerations for drainage in an artificial football ground?

Effective drainage is vital for an artificial football ground to prevent water accumulation and ensure year-round playability. This involves perforations in the turf's backing, a permeable sub-base (e.g., crushed stone), and proper grading of the underlying ground. Adequate drainage ensures rapid water runoff, protecting the turf and infill, and maintaining optimal playing conditions on the artificial football pitch.

· Q5: Is an artificial football ground safe for players compared to natural grass?

Modern artificial football pitches are designed with player safety as a top priority. They offer consistent shock absorption, reducing the impact on joints, and are engineered to minimize skin abrasions. The uniform surface also helps prevent twists and sprains associated with uneven natural turf. Independent testing and FIFA Quality Programme standards ensure that artificial grass football ground surfaces meet rigorous safety criteria.

· Q6: How does UV stability affect the lifespan and appearance of artificial football pitches?

UV stability refers to the turf's resistance to degradation from ultraviolet radiation. High-quality artificial grass football ground fibers are treated with UV stabilizers during manufacturing to prevent fading, brittleness, and structural breakdown over time. Excellent UV stability ensures that the artificial football ground retains its vibrant color and physical integrity for many years, even under intense sun exposure, crucial for an artificial football stadium.

· Q7: Can artificial football grounds be recycled at the end of their lifespan?

Recycling capabilities for artificial football pitches are continually improving. While historically challenging, advancements in technology now allow for the separation and repurposing of different components, such as the infill and turf fibers. XYGrass is committed to sustainable practices and can advise on recycling options and end-of-life management for your artificial football ground to minimize environmental impact.

1. FIFA Quality Programme for Football Turf.

2. ASTM F1551-09: Standard Test Methods for Comprehensive Characterization of Turf.

3. ISO 9001:2015 – Quality management systems – Requirements.

4. DIN 18035-7: Sports grounds – Part 7: Artificial turf pitches.

5. European Committee for Standardization (CEN) Standards for Artificial Sports Surfaces.

Hit enter to search or ESC to close